3MG Architects and Engineers (3MG), on behalf of Puerto Rico Industrial Development Company (PRIDCO), contracted ANAMAR to conduct an MPRSA Section 103 evaluation at the Mayagüez Waterfront Industrial Park (MWIP) to determine suitability of maintenance dredged material for ocean disposal in the Mayagüez ocean dredged material disposal site (ODMDS).

Project Statute

- MPRSA Section 103

Yabucoa Harbor is a small, open bay which is located between Punta Guayanés and Punta Quebrada Honda in the southeastern corner of Puerto Rico. It is a man-made harbor and navigation channel with a marine terminal that offers berthing facilities for deep draft tankers and a barge dock. Buckeye Caribbean Terminals, LLC (Buckeye) operates a marine terminal facility in Yabucoa Harbor. The facility has two docks with one deep water berth and two shallow water berths.

A major maintenance dredging event was performed in 1989 to deepen the navigation channel to -50 feet mean lower low water (MLLW). The last routine maintenance dredging for the Yabucoa Marine Terminal was performed by Buckeye and began in September 2017 and completed in October 2017 after Hurricane Maria. Since that dredging event, the depth along the navigation channel and turning basin have been significantly affected by accumulation of sediments, resulting in impacts to the maritime transit and operations at the Port of Yabucoa. To maintain Buckeye’s operations and navigational safety, maintenance dredging for the facility has become a priority.

ANAMAR was contracted to prepare a Sampling and Analysis Plan/Quality Assurance Project Plan (SAP/QAPP), collect sediment and water samples, conduct required analyses, and present the results in a report. The main objective of the testing program is to determine the suitability of maintenance material to be dredged from the project area for ocean disposal in the Yabucoa ODMDS.

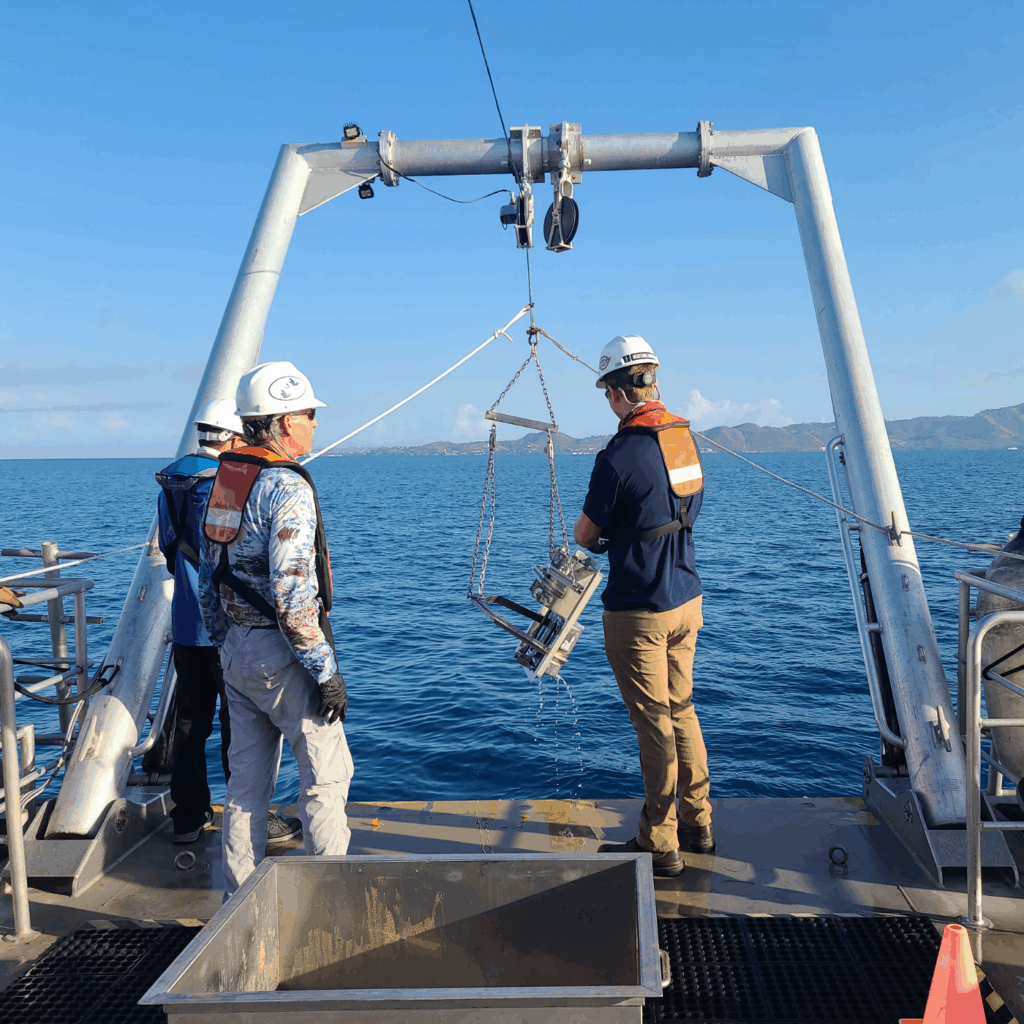

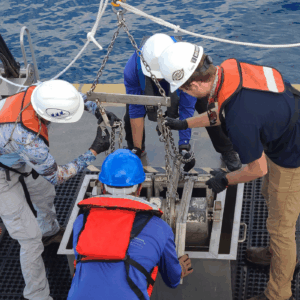

ANAMAR coordinated and directed all logistics and field sampling operations for this project, managed vibracore, offshore vessel, and laboratory subcontractors, coordinated shipping logistics of both equipment to/from the project site, and managed transport of samples to the laboratories within holding times and preservation required. The field operations, offshore reference sample collection in deep water, and shipping logistics for this project were complex given the relatively remote location of the project site. The ANAMAR team’s prior experience of working in Puerto Rico was critical to the successful planning and execution of sampling operations and sample shipment to the laboratories. The weather conditions during the field effort were challenging due to windy conditions and rough sea conditions. This required completing sampling on a compressed schedule to keep the project on schedule and avoid shipping delays.